Traceability is one of the greatest challenges faced by food and beverage manufacturers. Having products becoming contaminated by an unknown source is a nightmare.

According to an article published by Sage, there was an incident in Europe during 2013 in which foods advertised as beef were found to contain undeclared or improperly declared horse meat—as much as 100% in some cases. The incident became apparent when horse DNA was discovered in frozen beef burgers which were sold in various British and Irish supermarkets.

As a consequence of this event, the importance of traceability, or the ability to trace products as they pass through the often long and complex supply chain, really surfaced. Luckily, modern Enterprise Resource Planning (ERP) provides the food and beverage industry with full transparency—crucial for documenting and reporting on compliance.

Traceability allows distribution and manufacturing facilities to verify the history and location of a product through documented, recorded verification and significantly improves operations.

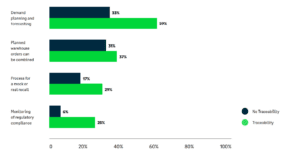

Again, according to an article published by Sage, leaders with traceability are four times more likely than followers to monitor for regulatory compliance, which gives them an ability as process manufacturers to recall products.

Source: “Use real-time product traceability to eliminate waste and delight customers,” Aberdeen Group, August 2017; % of respondents n = 85

With various new and emerging technologies, the food and beverage industries have the ability to record product transactions and essential product data. The insights that come out of this data are at the core of traceability.

To achieve full visibility of traceability in the supply chain, IoT, big data analytics and the cloud must be integrated into your ERP systems. They should be designed with the food and beverage manufacturer in mind—broad enough to log transactions across the supply chain, yet deep enough to offer you industry-specific functionality. These include logging of source materials, results analysis, a way to conduct preventative actions and adherence to strict regulations.

Sage 100 offers you a comprehensive, real-time solution that delivers accurate, up-to-date data that identifies and alleviates the consequences of product recalls and other supply chain issues. With Sage 100, your food and beverage business will have a faster, simpler, and flexible way to keep the costs and reputational damage of recalls to a minimum.

When you team up with ACC Software Solutions, you’ll receive a team of experts with over 25 years of industry experience to help determine the right solution for you and your business. Contact our staff today for your FREE consultation!

Solutions by Industry

What's New

Outgrowing Your ERP? Why Acumatica is the Upgrade You Need

Read MoreSubmitted by Stephanie Dean on Thu, 06/26/25 - 15:52

Why You Should Make the Switch: NetSuite to Acumatica

Read MoreSubmitted by Stephanie Dean on Tue, 06/17/25 - 13:36

Acumatica ERP for Sustainable Businesses

Read MoreSubmitted by Stephanie Dean on Thu, 05/29/25 - 10:37