We are on the cusp of the fourth industrial revolution, also known as Industry 4.0. With Cincinnati, Ohio declaring itself an “Industry 4.0 demonstration city,” the question isn’t if Industry 4.0 is coming, but rather how quickly. Technologies such as the Internet of Things (IoT), robotics and automation have ushered in this fourth age of widespread change. These technologies, along with Big Data and analytics, and cyber-physical systems sit at the heart of the Industry 4.0 model and they all run on the cloud. Over the next decade, these emerging technologies will create new real-time connections between machines, production processes, and systems that will revolutionize the way we do business.

The core principle of Industry 4.0 is that by connecting machines, workpieces, and systems, businesses are creating intelligent networks along the entire value chain that can control each other autonomously.

Just as the original Industrial Revolution changed the world, the current integration of resources and technology is poised to create another major industrial shift.

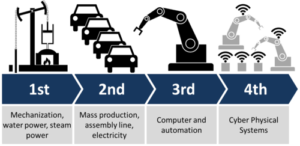

The modern world is universally acknowledged to have begun with the Industrial Revolution of the late eighteenth century. Harnessing the energy of water and steam to power machines enabled workers to produce goods more quickly, changing the world in the process. Then, there was electricity, the assembly line and the birth of mass production. The third industrial revolution came with the popularization of computers, robotics, and machines leading to the beginnings of automation by replacing humans on the assembly line. Now, cyber-physical systems will be used to monitor the physical processes and make decentralized decisions. The physical systems connect to the internet wirelessly, then communicate with each other and humans in real time to form the IoT and produce massive amounts of data. The Industry 4.0 model has been used to create Smart Factories.

Interoperability – Utilizing the IoT, machines, devices, sensors, and people that connect and communicate with one another.

Information Transparency – The systems create a digitized version of the physical world utilizing massive amounts of data generated by sensors in order to contextualize information.

Technical Assistance – First, the ability of the systems to support human decision-making and problem solving through data analysis, predictive analytics, and visualization. Second, to assist with tasks that are too dangerous or difficult for humans to complete unassisted.

Decentralized Decision-Making – The ability of cyber-physical systems to make simple decisions and become as autonomous as possible.

Modern information and communication technologies like the IoT, cyber-physical system, Big Data analytics, and cloud computing, will help early detection of defects and production failures, thus enabling their prevention and increasing productivity, quality, and agility benefits that have significant competitive value for early adopters.

The IoT has been made possible through the popularization of broadband internet and wifi to connect “things” to the internet or to each other. It is a fusion of all physical peripherals like software, sensors, electronics, etc. with internet and machine enabling data collection and transfer. Meaning, that the ability to connect with the internet and through the internet is no longer exclusively reserved for smartphones, tablets, and desktop computers. The IoT is built on cloud computing and networks of data-gather sensors, making it mobile, virtual and creating real-time connections from “thing” to “thing” and “thing” to “person.” This network of connected equipment in the Smart Factory will use data to manufacture, move, report, and learn at astounding rates, efficiently.

90% of the world’s data has been created in the last two years (source). Exponential amounts of data are being generated at all times. Every digital process or social media interaction generates it. Systems, sensors and mobile devices transmit it. In business terms, Big Data is a collection of data from traditional and digital sources inside and outside your company that represents a source for ongoing discovery and analysis. The challenge lies in taking these massive amounts of unstructured data, organizing it, and analyzing it order to extract valuable insights. By utilizing Big Data analysis, Smart Factories and solutions within those organizations will be able to make better, smarter decisions.

Cyber physical systems are integrations of computation, networking, and physical processes. Embedded computers and networks monitor and control the physical processes, with feedback loops where physical processes affect computations and vice versa. CPS integrates the dynamics of the physical processes with those of the software and networking, providing abstractions and modeling, design, and analysis techniques for the integrated whole. The notion centers on computers and software being embedded in devices where the first use is not computation, rather it is a loop of action and machine learning.

Cloud technology is a critical enabler of the next industrial revolution, by providing the means for businesses to innovate around these technologies. The increase in cloud infrastructure has made business processes easier, cheaper, and faster. However, the true potential of the cloud to support Industry 4.0 can be realized through the integration of computing services with a cloud platform. By tapping into the power of computing services, cloud platform tools support innovative and disruptive applications as they emerge.

Industry 4.0 will be built on robots that are more brains than brawn. They will integrate physical and cognitive ability to do more than heavy lifting or other repetitive tasks. Behavior-based robots are fueled by new innovations in Artificial Intelligence (AI) and are changing the way factories are organized, operate and perform. By integrating AI with robotics, robots can work semi-autonomously on a wide range of tasks. Robots will eventually share information and insight that improves performance factory-wide with the ability to learn from self and others (machine learning), correct self and others, collect, analyze, and share insights from data collected from multiple locations simultaneously.

In order to embrace the Fourth Industrial Revolution, manufacturers will need to prepare for disruptive technologies and a digital transformation. The emerging technologies highlighted above are and will increasingly power Smart Factories across the globe. These technologies will collect, use, and share data so that production can reach new heights in safety and efficiency. Taking a critical look at your existing IT solutions is the first step towards understanding how prepared your business is to become a Smart Factory by embracing Industry 4.0 technologies.

Check out Part 2 of this Industry 4.0 series to find out how an integrated ERP and MES solution set your manufacturing business up for success during the Fourth Industrial Revolution!

Learn more about our modern ERP solutions and contact us to start embracing Industry 4.0 technologies!

Solutions by Industry

What's New

Building a Smarter Business with Acumatica in 2026

Read MoreSubmitted by Stephanie Dean on Thu, 02/19/26 - 10:53

ERP Trends Driving Digital Transformation

Read MoreSubmitted by Stephanie Dean on Mon, 02/16/26 - 12:59

Preparing for Your Acumatica 2025 R2 Upgrade

Read MoreSubmitted by Stephanie Dean on Tue, 02/10/26 - 15:06